ABS sensor: how it works, common problems, repair costs

By Vlad Samarin April 30, 2023

The function of the ABS sensor is to measure the rotational speed of the wheel. There are four ABS sensors in a car; one for each wheel.

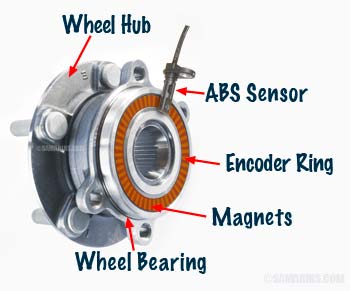

In technical literature, the ABS sensor is known as Wheel Speed Sensor or WSS.How the ABS sensor works: To produce a signal, a stationary ABS sensor is placed close to a ring that rotates together with the wheel. In many cars, it's an encoder ring that is a part of the wheel bearing side seal. Such a ring has built-in magnets that are placed at equal intervals.

Other cars have a ring with metal teeth (tone ring) that looks like a gear (in the photo below).

As the ring rotates beside the ABS sensor, it generates evenly spaced electric impulses or voltage spikes. The faster the wheel rotates, the higher the frequency of the spikes.

In most cars, ABS sensors are connected to the ABS control module (a.k.a. VSC or DSC control module). Signals from the wheel speed sensors are used for the operation of Vehicle Stability Control System (VSC) and several other systems. Read more about how the ABS sensor works below.

What happens when an ABS sensor stops working?

If the ABS sensor stops working, the Vehicle Stability Control system and the Antilock Braking system become disabled. In some modern cars, other safety systems may also become disabled. You might see several warning lights illuminated on the dash, including the Vehicle Stability System warning light, and possibly Electrical Power Steering, Check Engine warning lights as well as some others.If the ABS sensor signal cuts out intermittently, we know cases where it may cause the vehicle stability control to start kicking in by itself in normal driving conditions.

What causes ABS sensor problems?

There are two types of ABS Sensor faults: electrical and mechanical.- Electrical faults can be caused by a sensor that is going bad (e.g., due to corrosion) or a problem with the sensor connector, such as corroded terminals (in the photo).

For example, the service bulletin 05-003-21 for certain 2018-2020 Jeep Renegade and Compass models mentions the problem where the ABS sensor could fail as a result of water intrusion. The bulletin advises replacing the front or rear Wheel Speed Sensors if confirmed bad.

Another example of an electrical fault is when the sensor wire is damaged, chewed by rodents, corroded or shorted. In many cars the ABS sensor comes with the wire as one piece.

- Mechanical faults could be caused by a damaged encoder (tone) ring,

a loose or improperly installed wheel bearing or when foreign objects cause interference between the sensor and an encoder ring.

For example, in some cars, the tone ring that is built into the drive shaft can break like in this photo. In cases like this, the sensor may still be OK and only the tone ring, or if it doesn't come separately, a drive shaft may need to be replaced.

How can you tell which ABS sensor is bad?

There are cases when it's obvious which sensor has a problem. For example, if the Vehicle Stability Warning light comes on and your mechanic notices during an oil change that the tone ring is broken at one of the wheels, it's very likely caused the problem.If the VSC warning light comes on right after the wheel bearing replacement, something most likely went wrong with the installation of that bearing. For example, press-in wheel bearings have an encoding ring on one side. If the bearing is pressed the wrong side in, the ABS sensor won't work. Sometimes, the ABS sensor can also get damaged when replacing the wheel bearing.

From our experience, we also have seen many cases where the ABS sensor wire has been chewed by rodents, which is easy to see.

However, in most cases the vehicle needs to be properly diagnosed. The mechanic will have to scan the ABS system for trouble codes and follow the diagnostic process for the particular code.

Using a scan tool, it's also easy to check and compare live data from each ABS sensor when wheels are rotating. The scan tool will typically show the ABS sensor as Wheel Speed Sensor or WSS. If the signal from one WSS sensor is different from the others or has spikes or drops in the signal, the sensor has a problem.

How much does it cost to fix the ABS sensor problem?

It will depend on the exact cause. Your repair shop or dealer will charge you a flat fee for diagnosis and then present you with repair options. If it's just the sensor that is bad, it's not very expensive to replace. If the wheel bearing needs to be replaced, it will cost 1-2 hours of labor plus the part ($60-$160) for an average car.If the tone ring is broken and cannot be replaced separately, the drive shaft may need to be replaced, which is 1.5-2.0 hours of labor for the front drive shaft in an average car plus the parts. We advise to have the vehicle diagnosed at the dealer and then consider different repair options. Aftermarket parts are often cheaper.

How the ABS sensor works

ABS Sensors working with tone rings: The wheel speed sensor is mounted so that its tip is positioned close to the teeth of the metal tone ring. The wheel speed sensor is stationary. The tone ring is attached to the axle (drive shaft) and rotates together with the wheel.As the wheel rotates, teeth of the tone ring pass by the wheel speed sensor tip and change the magnetic field in the sensor. As a result, the sensor produces voltage impulses. Each tooth generates one impulse. For example, if the tone ring has 52 teeth, it means one full rotation of the wheel equals to 52 impulses.

ABS sensors working with wheel bearings: The active ABS sensor is mounted so that the tip of the sensor is close to the side of the wheel bearing. The inner side seal of the wheel bearing contains small magnets built in at equal distances from each other (Encoder Ring). Each magnet passing by the sensor generates an electric impulse.

The wheel speed sensor is typically connected to the ABS control module. The ABS control module (a.k.a., DSC or VSC module) monitors the speed of each wheel for the antilock brake function, which is to prevent wheels from locking up during braking.

If during emergency braking the ABS module receives the signal that one of the wheels is rotating much slower than the others (close to locking up), it reduces the hydraulic braking pressure to that wheel to prevent it from locking up. This helps the driver maintain control of the vehicle during emergency braking.